Tech & Toys

-

Sea Nymph sea trials part 1

I managed to get her finished to the point of being water tight and having all the electronics installed before going on holiday, below you can see a little video of her on the pond at the Warminster Pleasure Gardens.

You can read through all the posts about the Sea Nymph build here.

-

Glamping

Last week we visited my father down in Devon, having grown bored of the usual places to stay, we cast around for something a bit different. It wasn’t long before Jenny found The Wood Life. Which is essentially 9 acres of woodland in the middle of a massive field, with a big tent and a few other niceties in a clearing in the wood. Well, that turned out to be quite different to a hotel then!

It was hard work in places, but great fun. A few of the Instagram pics I shot are shown below. You can get a feel for the size of tent from the first pic, it is an Albion Canvas (Broken link

http://www.albioncanvas.co.uk/) Tsavao, configured with two bedrooms and a large kitchen/lounge/dinning area. Thankfully the owners have installed a nice wood burning range to heat the place. Although getting up at half six to build a fire was not something I would want to do every day!

-

Aerokit Sea Nymph build – part 6

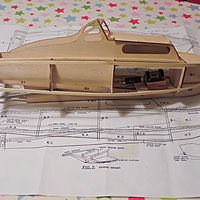

After a few busy evenings bending plywood and much sanding, construction is all but finished.I’ve given the entire boat two coats of resin Z Poxy finishing ). I have yet to finish the rudder servo cover/rear seats but I figure given it will be a removable hatch it can be built later.

I have never used resin as a finishing technique and I have to say I was a bit nervous, but I needn’t have been. It went on really nicely; two thin coats applied with a brush and excess wiped off with a sponge. The last coat will need a little cutting back with some wet and dry before I paint it.

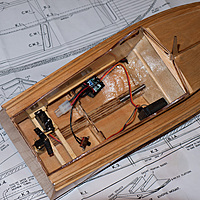

With the second coat dry I installed the radio gear which went in pretty easily because of the test fit before applying the side sheeting. Some thought will need to be given to securing the battery, current thinking is a Velcro strap attached to the keel.

After all that we were both as excited as each other to put her in the bath, I’m pleased to report all went well, happily going back and forth without sinking! The only water ingress appeared to be from the top of the rudder outer tube, although it was only very slight.

You can read through all the posts about the Sea Nymph build here.

-

Aerokit Sea Nymph build – part 5

I managed to get a good few hours yesterday alone and in peace to make some progress.

On Saturday night I gave all of the internals of the boat a coat of resin (Z-Poxy Finishing Resin). Hopefully all the areas I wont be able to access later are now sealed.

Then I decided to tackle the hull sheeting, which I have to admit I was not looking forward too! I roughed out a couple of carboard templates which helped a lot and before long I had to the two lower sheets attached.

Above you can see the lower right sheeting clamped on and drying.

Closeup of the nose showing a pencil line where I rough cut it before sanding to shape.

Two lower sheets applied and sanded to shape.

Next up; the side sheeting. I think it will look best overlapping the decking rather than the other way so I got the breasthook and side decking attached first. That is where things are now, the final pics show it all attached but not trimmed to shape. I have now sanded it back to the stringers ready for the sheets. Hopefully I’ll get them attached today.

Hopefully I’ll get to the side sheeting today, then the major construction will be finished although I still need some seat/hatch type structure at the back to cover the rudder servo.

You can read through all the posts about the Sea Nymph build here.

-

Aerokit Sea Nymph build - part 4

I had a bit of a think this afternoon, considering the options for the rudder servo. Initially I was going to try the closed-loop/pulley idea, but having had a root around in the spares box, found nothing suitable. So I plumped for the rudder at the back and some sort of seat to hide it option.

The rudder is in and the servo mounted on a couple of bearers, everything has been tested with the radio and seems fine.

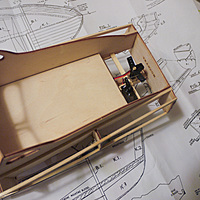

The next thing was the power pack. I had pondered splitting a pack into two 3 cell packs, but decided against this because my son and I sometimes still put these packs back in the HotShot. I’ve come up with a solution though, having eased the middle former a little (about 1/4") it fits without having to raise the cabin floor that much. It probably would look better lower but I’m happy with how it has gone together. I’ve also put little bearers around the outside of the hatch for it to rest on. Of course I am hoping that cutting a chunk out of the middle of that former wont weaken the boat too much! My thinking is that this boat was designed for a 1-1.5cc diesel which would cause a load more vibration and stress than my little leccy motor.

You can read through all the posts about the Sea Nymph build here.

-

ADSL Speed test

Mother in law ADSL speed in Westbury. BT Total Broadband.

-

Aerokit Sea Nymph build - part 3

I have managed to visit the local model shop where I bought a nice propshaft, prop, motor mount, UJ and a little ESC. The ESC is NiMH only, partly because I wanted to make use of some old NiMH cells, rather than my aircraft LiPos and partly because the model shop had nothing else in and I didnt fancy going elsewhere. So at some point in the future I’ll have to face up to getting a buggy pack in there. One thought I had was to split it into mini packs, but still wired the same way. Not thought much about that yet but it is a possibility.

As for tonights progress, I’ve all but completed the upper cabin area and the hatch. Everything needs shaping but it is all together. The one pain is there gap between the two upper windows, they were too short and I had no ply in, so I’ve left a gap and cut a wedge shape out of offcuts to fit in the gap, I’ll get that in tomorrow.

The biggest progress is the motor is now mounted. I had to lower the mount plate, cut some wedge shaped bearers and still had to shave a bit out of the plate because the motor was still sitting too low. It all feels solid though and the motor is a straight run to the prop shaft so I’m happy. The propshaft is still too long, I’ll get to that tomorrow.

So now I can’t avoid attending to the rudder. Gulp!

Last shot for tonight.

You can read through all the posts about the Sea Nymph build here.