Phoenix 2000 - update

I have managed a few updates since September when I added the page for the Phoenix. First off was fitting the flap servos in the wings, next I added a 5A sBEC because the BEC in the supplied ESC is said to not be up to the challenge of powering 6 servos. All was then well and I had a couple of flights over the weekend. The flaps seemed to work ok, more fiddling with regard to the amount of deflection is needed, and I’d like to try crow braking and full strip ailerons. Another day though!

Two things did occur to me though, firstly that plugging 4 servos into the receiver while rigging for each flight was somewhat tedious. And secondly on the last flight of that weekend (Sometime in November) an alarming amount of dihedral had developed in the wing, clearly something was amiss! I got her down again thankfully and started to investigate the cause of the flappy wings. At the time I discovered one of the ply plates in the wings had de-laminated completely, I could pull each of the layers of wood away from the next, this is not good! When I got back to London I cut two new 3/32" ply plates for the wings and a new ply joiner.

Over Christmas we were down in Wiltshire again so I got to glue in my new wing joiner plates. While waiting for the glue to dry I assembled the Weasel which I also store down there. And lo and behold, at the bottom of the bag was the carbon wing joining spar which I’d forgotten to install in the Phoenix! I’d even forgotten such a thing existed, what an utter fool. Oh well, no harm done. I was lucky to get her back in one bit and at least there are decent ply plates in the wings.

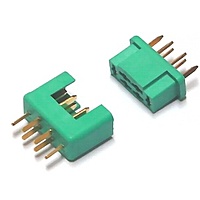

Next up was how to solve the problem of all those wires. I Googled a bit around the subject and found a lot of people using Multiplex connectors. These are 6 pin items, normally used as a battery connector, however because of the number of pins they make handy things for joining servo wires.

I’ve soldered both the servowires in one wing to a single male connector, and the same on the other wing panel, but using a female connector. Then all I had to do was take four servo extension leads, remove the sockets and solder them to a socket and a plug. Having one wing as female and one as male ensures I don’t get them mixed up when plugging everything in. 24 soldered connections, all wrapped in heatshrink tubing took a while but I think it was worth it. They make for very positive connections and feel a lot more robust than repeatedly plugging wires into a receiver.

Thats all for now, I’m not sure when our next trip down to the West country will be, but I’m looking forward to it.

Subscribe via RSS